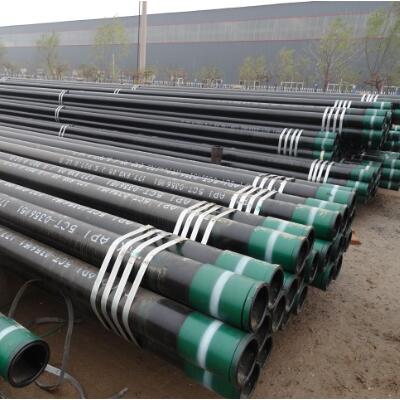

API 5CT Casing & Tubing Supplier, Manufacturer, Exporter

API 5CT Casing is the lifeline for maintaining oil well operations. Due to different geological conditions, the state of the downhole is complicated, and the combined action of tension, compression, bending and torsion stress acts on the pipe body, which puts high requirements on the quality of the casing itself. Once the casing itself is damaged for some reason, it may result in a reduction in production and even scrapping of the entire well.

Require Quotation? Send E-mail to : [email protected]

Casing & Tubing API 5CT Application: Used as the structural retainer for the walls of oil, gas wells

API 5CT Casing, API 5CT Tubing Specification:

OD: 4 1/2’’ ~ 20’’ (114.3mm ~ 508mm)

WT: 0.205’’ ~ 0.635’’ (5.21mm ~ 16.13mm)

LENGTH: R1, R2, R3

Standard: API 5CT J 55/K55/N80/C75/L80/C90/T95/Q125

Process Type: Seamless (SMLS), Electric Resistance Welded (ERW)

End: Beveled, Square Cut, With LTC/STC/BTC/VAM Connection

Surface: Anti-corrosion Water Based Paint

Packing: Protection Caps in both end, Waterproof Paper Wrapped, Two Tags

API 5CT Casing, API 5CT Tubing Tolerance:

| Types of steel tubes | Outer Diameter | Wall Thickness | |

| Cold-rolled tubes | Tube sizes(mm) | Tolerances(mm) | Tolerances(mm) |

| <114.3 | ±0.79 | -12.5% | |

Chemical Composition – API 5CT Casing, API 5CT Tubing

| Standard | Grade | Chemical compositions(%) | |||||||||

| API SPEC 5CT | J55 | C | Si | Mn | P | S | Cr | Ni | Cu | Mo | V |

| K55 | 0.34~0.39 | 0.20~0.35 | 1.25~1.50 | ≤0.020 | ≤0.015 | ≤0.15 | ≤0.20 | ≤0.20 | / | / | |

| N80 | 0.34~0.38 | 0.20~0.35 | 1.45~1.70 | ≤0.020 | ≤0.015 | ≤0.15 | / | / | / | 0.11~0.16 | |

| L80 | 0.15~0.22 | ≤1.00 | 0.25~1.00 | ≤0.020 | ≤0.010 | 12.0~14.0 | ≤0.20 | ≤0.20 | / | / | |

| P110 | 0.26~0.395 | 0.17~0.37 | 0.40~0.70 | ≤0.020 | ≤0.010 | 0.80~1.10 | ≤0.20 | ≤0.20 | 0.15~0.25 | ≤0.08 | |

Mechanical Properties – Casing & Tubing API 5CT

| Grade | Type | Total elongation under load (%) | Yield strength (min) | Yield strength (max) | Tensile strength min Mpa | Hardness Max (HRC) | Hardness Max(HBW) |

| J55 | – | 0.5 | 379 | 552 | 517 | – | – |

| K55 | – | 0.5 | 379 | 552 | 655 | – | – |

| N80 | 1 | 0.5 | 552 | 758 | 689 | – | – |

| N80 | Q | 0.5 | 552 | 758 | 689 | – | – |

| L80 | 1 | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 9Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| L80 | 13Cr | 0.5 | 552 | 655 | 655 | 23 | 241 |

| C90 | – | 0.5 | 621 | 724 | 689 | 25.4 | 255 |

| C95 | – | 0.5 | 655 | 758 | 724 | – | – |

| T95 | – | 0.5 | 655 | 758 | 724 | 25.4 | 255 |

| P110 | – | 0.6 | 758 | 965 | 862 | – | – |

| Q125 | All | 0.65 | 862 | 1034 | 931 | – | – |