316 is an improved version of 304 due to the addition of molybdenum and a slightly higher nickel content. The resultant composition of 316 gives the steel improved corrosion resistance in many aggressive environments. The molybdenum makes the steel

more resistant to pitting and crevice corrosion in chloride-contaminated media, seawater and to acetic acid vapours. The lower rate of general corrosion in mildly corrosive environments gives the steel good atmospheric corrosion resistance in polluted marine atmospheres.

316 offers higher strength and better creep resistance at higher temperatures than 304. 316 also provides excellent mechanical and corrosion properties at sub-zero temperatures. When there is a danger of corrosion in the heat-affected zones of weldments, the lower-carbon variety 316L should be used.

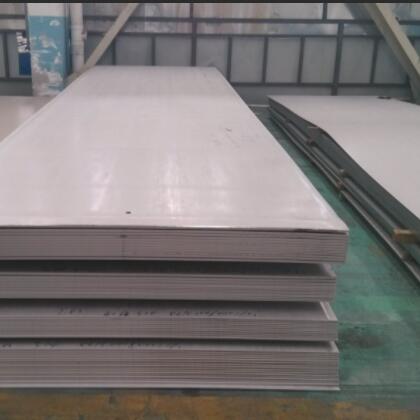

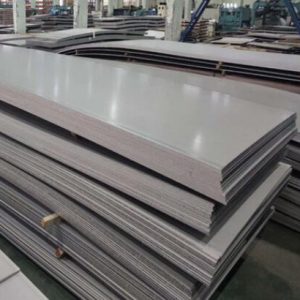

Available thicknesses for Stainless Steel 316/316L:

| 3/16″ | 1/4″ | 5/16″ | 3/8″ | 7/16″ | 1/2″ | 9/16″ | 5/8″ | 3/4″ | 7/8″ | 1″ | 1 1/8″ |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 4.8mm | 6.3mm | 7.9mm | 9.5mm | 11.1mm | 12.7mm | 14.3mm | 15.9mm | 19mm | 22.2mm | 25.4mm | 28.6mm |

| 1 1/4″ | 1 3/8″ | 1 1/2″ | 1 5/8″ | 1 3/4″ | 2″ | 2 1/4″ | 2 1/2″ | 2 3/4″ | 3″ | 3 1/4″ | 3 1/2″ |

| 31.8mm | 34.9mm | 38.1mm | 41.3mm | 44.5mm | 50.8mm | 57.2mm | 63.5mm | 69.9mm | 76.2mm | 82.6mm | 88.9mm |

| 3 3/4″ | 4″ | 4 1/4″ | 4 1/2″ | 4 3/4″ | 5″ | 5 1/4″ | 5 1/2″ | 5 3/4″ | 6″ | ||

| 95.3mm | 101.6mm | 108mm | 114.3mm | 120.7mm | 127mm | 133.4mm | 139.7mm | 146.1mm | 152.4mm | ||

Stainless Steel 316 (UNS S31600) and 316L (UNS S31603) are molybdenum-bearing austenitic stainless steels, which are more resistant to general corrosion and pitting/crevice corrosion than the conventional chromium-nickel austenitic stainless steels such as Stainless Steel 304. These alloys also offer higher creep, stress-to-rupture, and tensile strength at elevated temperatures. In addition to excellent corrosion resistance and strength properties, the Stainless Steel 316 and 316L Cr-Ni-Mo alloys also provide excellent fabricability and formability which are typical of the austenitic stainless steels.