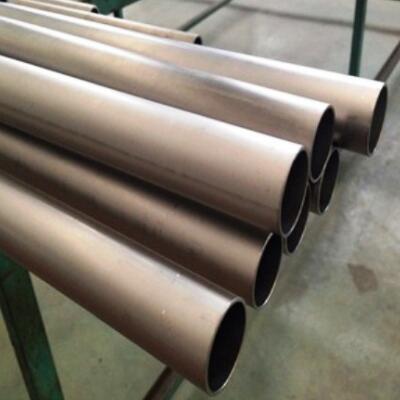

A270 Stainless Steel Sanitary Pipes/Tubes Manufacturers & Suppliers in China – SS 304 & SS 316 Sanitary Pipes & Tubes

Our stainless steel sanitary pipes and tubes are certified to the requirements of ASTM A269/270/312, 3A standards and most user specifications. Yingke manufactures stainless steel tubing from the finest quality raw materials. Stainless steel sanitary tubes in grade 304L and 316L are generally available in stock in size range of 1/2″ to 8″ OD.

Require Quotation? Send E-mail to : [email protected]

Stainless Steel A270 Sanitary Pipes & Tube Supply Range

| Size | 12-168mm |

| W.T | 0.7-3.0mm |

| Standard | ASTM A270, ASTM A249 |

| Grades | 304 / 304L / 316 / 316L / 409L / 430 |

| Length | 3000mm ~ 6000mm |

| Surface treatment | No.1 – 2B – Matte finish -#180 – #240 – #320 – #400 Bright – #600 Bright – 6K Mirror – 8K Mirror – Hair Line |

Chemical Composition for Stainless Steel Sanitary Pipes & Tubes, A270

| Grade | UNS | Composition, % | ||||||||

| Design | C | Mn | P | S | Si | Cr | Ni | Mb | Ti | |

| TP304 | S30400 | 0.08 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–11 | – | – |

| TP304L | S30403 | 0.035 | 2 | 0.045 | 0.03 | 1 | 18.0–20 | 8.0–13 | – | – |

| TP316 | S31600 | 0.08 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–14 | 2.00–3 | – |

| TP316L | S31603 | 0.035 | 2 | 0.045 | 0.03 | 1 | 16.0–18 | 10.0–14 | 2.00–3 | – |

| TP321 | S32100 | 0.08 | 2 | 0.045 | 0.03 | 1 | 17.0–19 | 9.0–12 | – | Ti 5 × (C+N) min, 0.70 max |

Quality and Mechanical Tests for Stainless Steel Sanitary Pipes & Tubes as per ASTM A270

To assure the highest quality standards, the tubing is subjected to extensive testing and inspection programs that meet or exceed ASTM A270 A1016 A1016M test requirements. Testing includes reverse bend, reverse flattening, and flange tests. Eddy current testing is performed on 100% of the sanitary tube produced.

Heat Treatment (Annealing) for Stainless Steel Sanitary Pipes & Tubes as per ASTM A270

Inline hydrogen bright annealing to 1900°F (1040° C) minimum followed with a rapid quench.

Surface Finishes for Stainless Steel Sanitary Pipes & Tubes as per ASTM A270

Surface finish is 20 µ-in Ra (0.5 µm) ID maximum, 30 µ-in Ra (0.8 µm) OD maximum surface roughness measured per ASME ANSI B46.1 with the profilometer reading at 90 degrees to the lay. Other finishes available upon request.

Flattening Test for Stainless Steel Sanitary Pipes & Tubes as per ASTM A270

For material heat treated in a continuous furnace flattening tests shall be made on a sufficient number of pipes to constitute 5 % of the lot, but in no case less than 2 lengths of pipe.

Markings for Stainless Steel Sanitary Pipes & Tubes as per ASTM A270

Bright annealed tubing is line–stenciled with OD, wall, ASTM specifications, size, grade, heat number, production date and time. OD polished tube is marked on one end of each tube with a removable label stating ASTM specification, manufacturer, grade and heat number. Continuous line stencil available on request.

Note:

- Mill test certificates will be issued according to EN10204.3

All tubes shall be supplied as per applicable ASTM A270