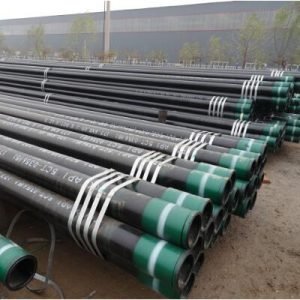

ASME SA335 P91 / ASTM A335 P91 Seamless Pipe UNS K91560 Alloy Steel Seamless Tube

Yingke supplies ASME SA335 / ASTM A335 P1 P2 P5 P9 P11 P12 P22 P91 P92 Alloy Steel Tube Seamless Pipe & Fittings

Require Quotation? Send E-mail to : info@yksteelpipe.com

ASME SA335 / ASTM A335 Grade P91 Alloy Steel Seamless Pipes, SA335 p91 Pipes Manufacturers, Exporters, Stockists & Suppliers.

Seamless Pipes / ASTM A335 Gr P91 Alloy Steel Pipes Stockiest, Manufacturer, Exporter & Suppliers

Standard: NF,ISO,DIN,ANSI,JIS,BS,EN

p91 alloy pipe, p91 seamless pipe is a chrome moly alloy metal that contains excellent strength and temperature resistance. It is designed for enhanced creep strength, making it a creep strength enhanced ferritic (CSEF). This metal is made by normalizing at 1050 °C, air cooling to 200 °C, and then tempered through heating to 760 °C. This process is the main reason behind ASTM A335 P91 Pipe’s creep strength and durability. ASTM A335 P91 stands for the metal’s composition of 9% chrome and 1% molybdenum plus vanadium. The chrome increases temperature strength and oxidation resistance. The molybdenum increases the elasticity, resistance to wear, and high temperature creep strength

Specification Of ASME SA335 P91 / ASTM A335 P91 Pipe & Tubes:

| Size |

: |

NPS 1/4” to NPS 36” |

| Standards |

: |

ASTM A335, ASME SA335, UNS K91560 |

| Type |

: |

Seamless |

| Outer Dimensions |

: |

10.3mm – 914.4mm |

| Wall Thickness |

: |

2.0mm – 60 mm |

| Length |

: |

max 12000mm |

| Schedule |

: |

Schedules 20 through 160, STD, XS, XXS. |

| Tubing End |

: |

Plain End, Beveled End etc. |

| Package |

: |

Packing in bundles, special packing can be offered by customers’ requirement |

| Remark |

: |

We could produce as per client’s special request . |

p91 alloy pipe, p91 seamless pipe Chemical Compositions :

| C, % |

Mn, % |

P, % |

S, % |

Si, % |

Cr, % |

Mo, % |

V, % |

N, % |

Ni, % |

Al, % |

Nb, % |

| 0.08-0.12 |

0.3-0.6 |

0.02 max |

0.01 max |

0.2-0.5 |

8.0-9.5 |

0.85-1.05 |

0.18-0.25 |

0.03-0.07 |

0.4 max |

0.04 max |

0.06-0.10 |

p91 alloy pipe, p91 seamless pipe Mechanical Properties :

| Tensile Strength , MPa |

Yield Strength, MPa |

Elongation, % |

Hardness, HB |

| 585 min |

415 min |

20 min |

250 max |

p91 alloy pipe, p91 seamless pipe Wall Thickness :

| NPS [DN] Designator |

Tolerance, % from Specified |

|

Over |

Under |

| 1/8 to 2 1/2 [6 to 65] incl., all t/D ratios |

20.0% |

12.5% |

| Above 2 1/2 [65], t/D < or = 5% |

22.5% |

12.5% |

| Above 2 1/2 [65], t/D > 5% |

15.0% |

12.5% |

| (t = Specified Wall Thickness; D = Specified Outside Diameter) |

|

|