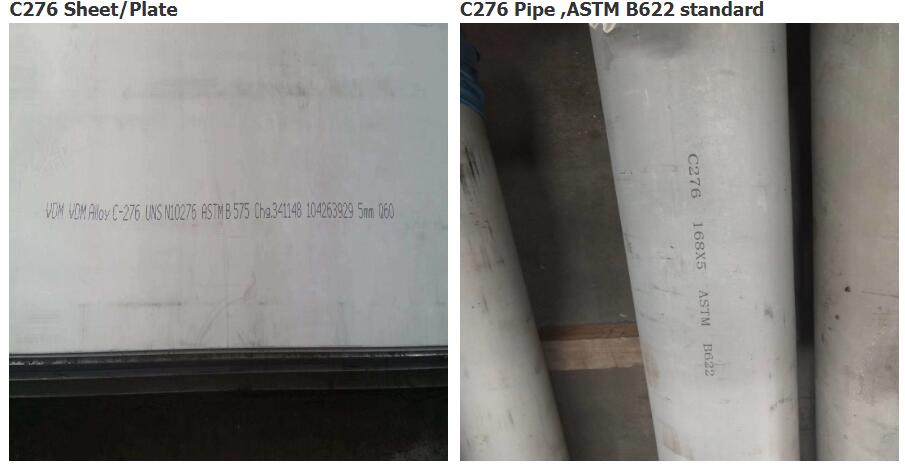

Hastelloy C-276 Nickel Alloy Tube & Pipe Suppliers, Manufacturers, Exporter

UNS Number N10276 / Other common names: Alloy C276, Hastelloy® C-276

Yingke supplies Hastelloy® alloys B-2, B-3, C22, C276, X, G30 in the form of Plate, Sheet, Bar, Wire, Pipe, Tubing, Pipe Fittings, Flanges

Require Quotation? Send E-mail to : [email protected]

Standard: NF,ISO,DIN,ANSI,JIS,BS,EN

Alloy C-276 Hastelloy Tube & Pipe Fittings is widely used in the most severe environments such as chemical processing, pollution control, pulp and paper production, industrial and municipal waste treatment, and recovery of sour natural gas.

Chemical Composition: Hastelloy C276 Tube, Alloy 276 tube

| Alloy | % | Ni | Cr | Mo | Fe | W | Co | C | Mn | Si | V | P | S |

| C | Min | Rest | 14.5 | 15 | 4 | 3 | |||||||

| Max | 16.5 | 17 | 7 | 4.5 | 2.5 | 0.08 | 1 | 1 | 0.35 | 0.04 | 0.03 | ||

| C276 | Min | Rest | 14.5 | 15 | 4 | 3 | |||||||

| Max | 16.5 | 17 | 7 | 4.5 | 2.5 | 0.01 | 1 | 0.08 | 0.35 | 0.04 | 0.03 |

Hastelloy C-276 Physical properties

| Density | 8.9 g/cm³ |

| Melting point | 1325-1370 °C |

Hastelloy C276 Tube, Alloy 276 tube

minimum mechanical properties in the room temperature

| Alloy status | Tensile strength Rm N/mm² |

Yield strength

RP0.2 N/mm² |

Elongation A5 % |

| Solution treatment | 690 | 283 | 40 |

Hastelloy C276 Tube, Alloy 276 tube Features

- Excellent corrosion resistance in reducing environments

- Exceptional resistance to strong solutions of oxidizing salts, such as ferric and cupric chlorides

- High nickel and molybdenum contents providing good corrosion resistance in reducing environments

- Low carbon content which minimizes grain-boundary carbide precipitation during welding to maintain resistance to corrosion in heat-affected zones of welded joints

- Resistance to localized corrosion such as pitting and stress-corrosion cracking

- One of few materials to withstand the corrosive effects of wet chlorine gas, hypochlorite and chlorine dioxide