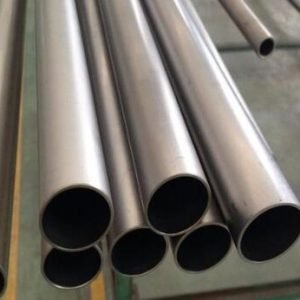

Some of the most common types of mechanical tubing include mandrel tubes (DOM), hot rolled / finished seamless tubes (HRS), cold drawn seamless tubes (CDS), hot-rolled or cold-rolled welded tubes (hrew / crew), and 4140 alloy tubes.

AVAILABLE SHAPES:

- Square

- Rectangle

- Round

- Custom Shapes (Must be large quantities)

SIZE RANGE:

- Square – From 0.500” to 2.500”

- Rectangle – From 1.000” x 0.500” to 4.000” x 2.000”

- Round – From 0.125” OD to 26.000” OD

Require Quotation? Send E-mail to : info@yksteelpipe.com

MECHANICAL TUBING APPLICATION

Tubing used for mechanical and light gauge structural applications. Mechanical tube is produced to meet specific end use requirements, specifications, tolerances and chemistries. This allows for more specific property uniformity throughout the tube compared to standard pipe or tube. While Mechanical tube can be produced to standard specifications when requested, it is often produced to “typical” properties that focus mainly on the yield strength for a precise size and wall thickness. In some applications with severe forming, yield strength may not even be specified and the mechanical tube is produced to be “fit for use”. Mechanical tubing encompasses a wide range of both structural and non-structural applications.